Your family-owned source for American-made quality Specialty Chemical Products

Solutions

for Industry

Made in the U.S.A.

SOLUTION 70 SILICONE DIELECTRIC GREASE is a non-curing silicone paste lubricant. It protects, seals, waterproofs, and electrically insulates metal parts. Creates a moisture barrier for electrical contacts, helping to prevent arcing, and conductive film from forming on electric mounts and insulators. Can be used as a rubber, and plastic parts lubricant, or ball valve lubricant. Use as a mold release agent. Works well as a packing lubricant for shafts and valve stems. Can be used as a plug or ,stopcock lubricant.

Solution 70 – SILICONE DIELECTRIC GREASE |

|||||

| Stock Code | Contents | Container | Units per Case | Weight per Case (lbs.) | |

| 52000 | 5 OZ | TUBE | 12 | 5 | |

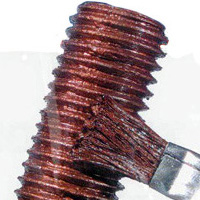

SOLUTION 800 LOW FRICTION MOLY LUBRICANT is a premium molybdenum disulfide lubricant paste formulated specifically for lubricating and protecting metal surfaces under extreme pressure.

Solution 800 provides a low friction coefficient which reduces friction and high wear. Prevents metal-to-metal contact. When used as an antiseize, protects parts from corrosion, rust, galling and seizing. Withstands temperatures to 800ºF as a lubricant and 2400ºF as an antiseize.

We recommend LOW FRICTION MOLY LUBRICANT for use on:

|

LOW FRICTION MOLY LUBRICANT can be used in:

|

Solution 800 – LOW FRICTION MOLY LUBRICANT |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 20102 | BLACK | 8 OZ. | Brush Top Can | 12 | 8 |

| 20106 | BLACK | 1 LB. | Brush Top Can | 12 | 14 |

| 20111 | BLACK | 11 LB. | Flat Top Can | 2 | 24 |

| 20114 | BLACK | 55 LB. | Pail | 1 | 59 |

| 20116 | BLACK | 425 LB. | Drum | 1 | 465 |

Solution 801 Is a premium Molybendum disulfide lubricant paste formulated specifically for high stress bolting applications.

Solution 801 provides a low friction coefficient which reduces friction and high wear even in extreme environments. Has excellent lubricity, protects bolts and threads from corrosion, rust, galling and seizing allowing for consistent torqueing values. Withstands temperatures to 800ºF as a lubricant and 2400ºF as an antiseize.

We recommend EXTREME MOLY LUBRICANT for use on:

|

EXTREME MOLY LUBRICANT can be used in:

|

Solution 801 – EXTREME MOLY LUBRICANT |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 20107 | BLACK | 1 LB. | Brush Top Can | 12 | 14 |

| 20115 | BLACK | 15 lb | Gallon Can | 2 | 32 |

SOLUTION 1000 FOOD GRADE ANTISEIZE is formulated specifically for use at food processing plants in which contact to food may occur. This product is safe for incidental food contact.

SOLUTION 1000 protects stainless steel and other alloy materials found in the food industry. Prevents seizing, galling, rust and corrosion. Lubricates stainless bolt threads while easing assembly and disassembly of metal fasteners. SOLUTION 1000 has excellent water resistance. Material is a soft white antiseize paste and is temperature resistant to 1000ºF. Meets MIL-A-907-E.

SOLUTION 1000 contains only ingredients recognized by the FDA as safe for incidental food contact, as published in 21 CFR, Parts 170-190.

We recommend FOOD GRADE ANTISEIZE for use on:

|

FOOD GRADE ANTISEIZE can be used in:

|

Solution 1000 – FOOD GRADE ANTISEIZE |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 10302 | WHITE | 8 OZ. | Brush Top Can | 12 | 8 |

| 10306 | WHITE | 1 LB. | Brush Top Can | 12 | 14 |

| 10347 | WHITE | 2 LB. | Flat Top Can | 12 | 29 |

| 10353 | WHITE | 40 LB. | Pail | 1 | 45 |

| 10316 | WHITE | 425 LB. | Drum | 1 | 465 |

SOLUTION 1800 is a general purpose antiseize formulated with copper, aluminum and graphite in a high-quality grease. This silver color antiseize protects parts from corrosion, rusting, galling, and seizing. Eases assembly and disassembly of metals parts. Lubricates bolt threads while reducing friction and wear. Meets MIL-A-907-E.

We recommend ALUMINUM COPPER ANTISEIZE (SILVER COLOR) for use on:

|

ALUMINUM COPPER ANTISEIZE (SILVER COLOR) can be used in:

|

Solution 1800 – ALUMINUM COPPER ANTISEIZE (SILVER COLOR) |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 10501 | SILVER | 4 OZ. | Brush Top Can | 12 | 4 |

| 10502 | SILVER | 8 OZ. | Brush Top Can | 12 | 8 |

| 10506 | SILVER | 1 LB. | Brush Top Can | 12 | 14 |

| 10510 | SILVER | 8 LB. | Flat Top Ca | 2 | 18 |

| 10514 | SILVER | 42 LB. | Pail | 1 | 46 |

| 10516 | SILVER | 425 LB. | Drum | 1 | 465 |

SOLUTION 2000 is a premium copper/graphite blend antiseize specifically formulated for high temperature applications. SOLUTION 2000 protects parts from corrosion, rust, galling, and seizing. Lubricates bolt threads while easing assembly and disassembly of metal parts. For use with most metals and is non-corrosive. Will extend fastener life. Meets MIL-A-907-E. Temperature resistant to 2000ºF.

We recommend COPPER ANTISEIZE for use on:

|

COPPER ANTISEIZE can be used in:

|

Solution 2000 – COPPER ANTISEIZE |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 10101 | COPPER | 4 OZ. | Brush Top Can | 12 | 4 |

| 10102 | COPPER | 8 OZ. | Brush Top Can | 12 | 8 |

| 10103 | COPPER | 10 OZ. | Brush Top Can | 12 | 9 |

| 10104 | COPPER | 1 LB. | Flat Top Ca | 12 | 15 |

| 10106 | COPPER | 1 LB. | Brush Top Can | 12 | 14 |

| 10108 | COPPER | 2.5 LB. | Flat Top Can | 12 | 35 |

| 10110 | COPPER | 8 LB. | Flat Top Can | 2 | 18 |

| 10112 | COPPER | 25 LB. | Pail | 1 | 28 |

| 10114 | COPPER | 42 LB. | Pail | 1 | 46 |

| 10116 | COPPER | 425 LB. | Drum | 1 | 465 |

| 10175 | COPPER | 12 OZ. | Aerosol | 12 | 13 |

| 10190 | COPPER | 2 Grams | Pouch | 125 | 13 |

SOLUTION 2400 MARINE GRADE ANTISEIZE is formulated for all heavy duty marine applications. Solution 2400 protects fasteners and assemblies from corrosion and rust caused by fresh and salt water, humidity, and extreme marine conditions. It has excellent resistance to water and water wash-out. temperature-resistant to 2400ºF. Prevents metal-to-metal contact. Eases assembly and disassembly of metal parts while reducing friction and wear.

We recommend MARINE GRADE ANTISEIZE for use on:

|

Solution 2400 – MARINE GRADE ANTISEIZE |

|||||

| Stock Code | Contents | Container | Units per Case | Weight per Case (lbs.) | |

| 10802 | 8 OZ. | Brush Top Can | 12 | 8 | |

| 10806 | 1 LB. | Brush Top Can | 12 | 16 | |

| 10810 | 8 LB. | Gallon Can | 2 | 18 | |

SOLUTION 2500 is a premium grease, calcium, and graphite blend which has been formulated for heavy duty applications. It is lead free and contains no copper or nickel, making it the preferred choice of refineries and chemical plants. SOLUTION 2500 protects parts from corrosion, rust, galling and seizing. Lubricates bolt threads while easing assembly and disassembly of metal parts, including stainless steel and soft metals. SOLUTION 2500 is non-corrosive and prevents metal to metal contact. Temperature resistant to 2500ºF. Meets MIL-A-907-E.

We recommend METAL FREE ANTISEIZE for use on:

|

METAL FREE ANTISEIZE can be used in:

|

Solution 2500 – METAL FREE ANTISEIZE |

|||||

| Stock Code | Contents | Container | Units per Case | Weight per Case (lbs.) | |

| 10602 | 8 OZ. | Brush Top Can | 12 | 8 | |

| 10606 | 1 LB. | Brush Top Can | 12 | 16 | |

| 10608 | 2 LB. | Flat Top Can | 12 | 32 | |

| 10654 | 45 LB. | Pail | 1 | 50 | |

| 10616 | 425 LB. | Drum | 1 | 465 | |

SOLUTION 2600 is a premium nickel/graphite blend antiseize specifically formulated for extreme temperatures. This antiseize also provides excellent chemical resistance. SOLUTION 2600 protects parts from corrosion, rust, galling and seizing. Lubricates bolt threads while easing assembly and disassembly of metal parts, including stainless steel and soft metals. SOLUTION 2600 is copper and lead-free, non-corrosive, and acid resistant. Meets MIL-A-907-E. Temperature resistant to 2600ºF.

We recommend NICKEL ANTISEIZE for use on:

|

NICKEL ANTISEIZE can be used in:

|

Solution 2600 – NICKEL ANTISEIZE |

|||||

| Stock Code | Color | Contents | Container | Units per Case | Weight per Case (lbs.) |

| 10202 | GRAY | 8 OZ. | Brush Top Can | 12 | 8 |

| 10204 | GRAY | 1 LB. | Flat Top Can | 12 | 15 |

| 10206 | GRAY | 1 LB. | Brush Top Can | 12 | 14 |

| 10210 | GRAY | 8 LB. | Flat Top Ca | 2 | 19 |

| 10214 | GRAY | 42 LB. | Pail | 1 | 46 |

| 10216 | GRAY | 425 LB. | Drum | 1 | 465 |